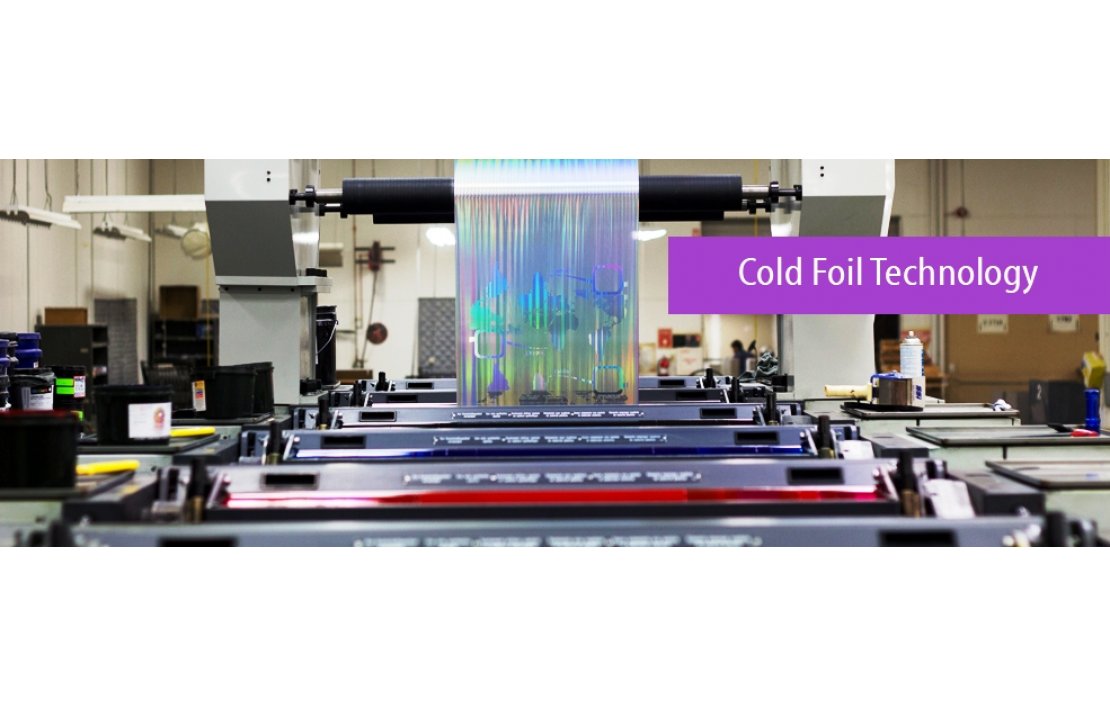

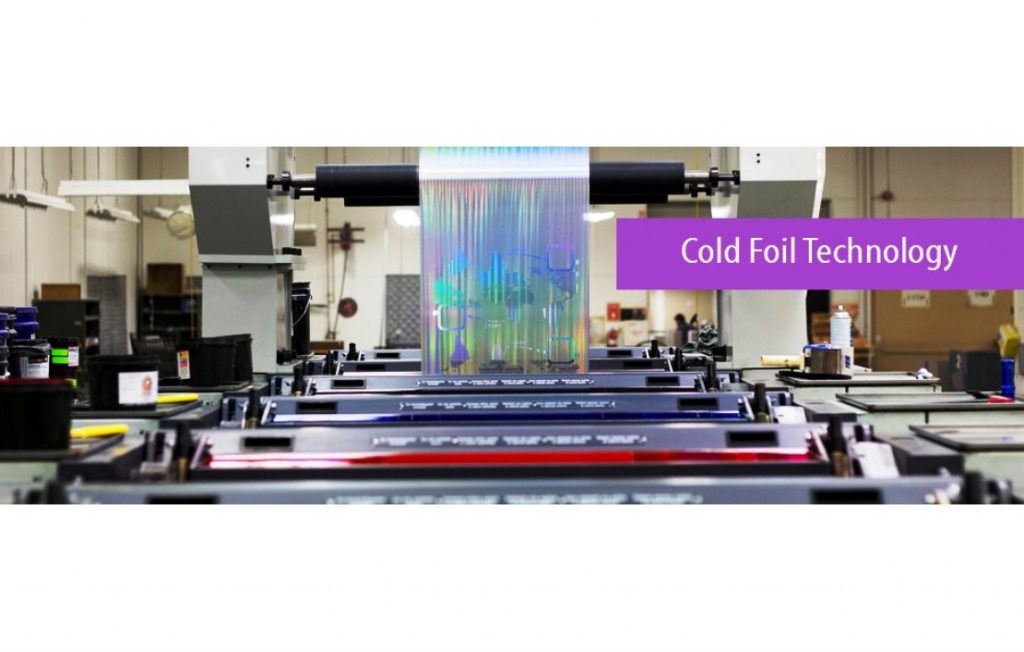

Cold foiling units can be installed on your offset Heidelberg machines as well as offline units. We can provide you both types of units with installation and Cold Foils materials as well. Cold foils can be silver metallic, golden and in Holographic patterns.

Features of offset cold foil stamping :

1) Enhancing the utility of the foil

a. The most important feature is “saving foils aiming at environmental protection”. It is driven by servo motors to deliver the foil. According to the cold foil images’ size, this system can automatically jump forward or backward to enhance the utilization of foil.

b. Allowing multiple strips of foils to be used.

2) Achieving metallic effect of delicate lines, words and half-hue

Patterns.

3) Replacing Hot Stamping plate, high cost of flexography cold foil and complicated courses —-by applying of PS plate

4) Strong flexibility

a. Cold Foil—Printing / Printing – Cold Foil

b. Easily working with your existing facilities

5) Cold foil with printing effects would replace many different hot foils.

Our dedicated packaging specialist is there to update you about all the new custom packaging techniques. What are u waiting just dial +1(732)481-2937 or email us at sales@customboxesclub.com

for more details.