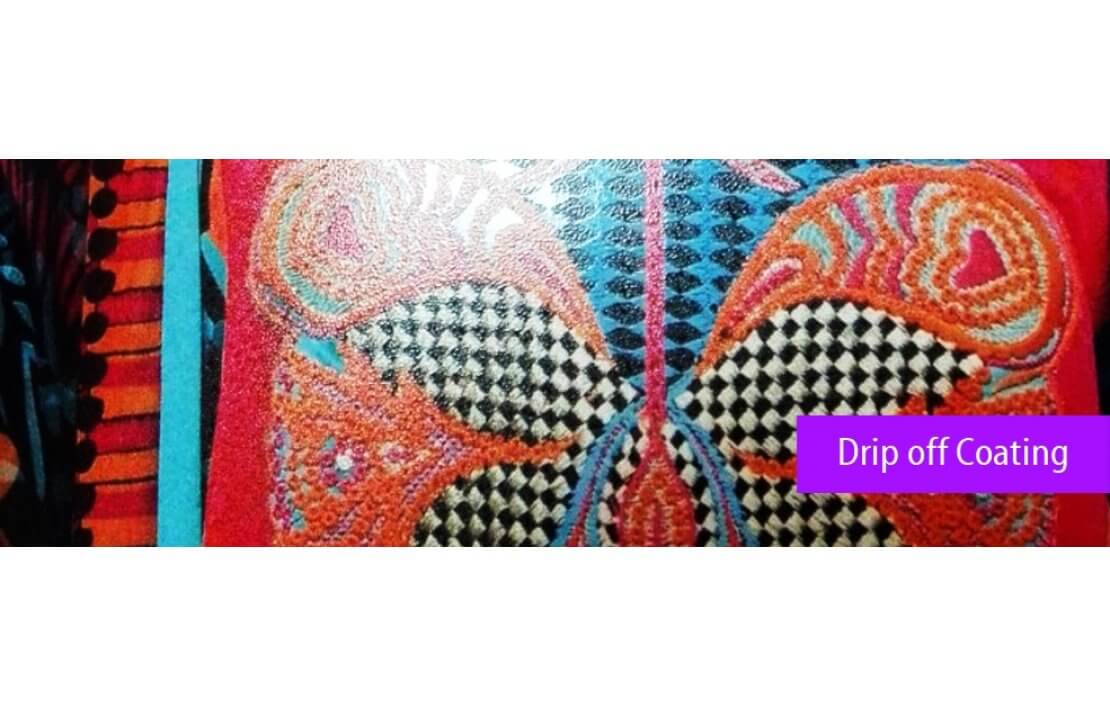

Hybrid Drip off Coatings:

In the last few years many technologies have been emerged that reshaped the present senerio of printing and packaging industry.Some new technologies inducted in the form of modern printing equipment and some in the form of print finishing techniques like Drip Off Coatings and use of many effect varnishes having different printed effects.The end goal is to create value addition and Anticounterfeiting which help brands to stand out and to grow without any fear of Counterfeiting.

Drip off coating is a finishing process that catches customer attention by adding value, glamour and prestige to the printed substrate. This process can be done by in-line and off-line process. It can be water based, oil based and UV based. A high speed sheet offset press with inline coater is required to achieve this finishing effect.We can acheive matt or repellent effects sometimes looks texture or coarse sand.Visually they are magical but the true feel comes when we touch the printed box ,catalogue or substrate.

. The purpose behind is to give a competitive advantage in packaging to the brand owners which can help them to boost the value and sales. There are varieties of products especially in cosmetic, decorative and gift presentations industry where packaging plays a decisive role to purchase the product. More attractive is the packaging it will yield more sales..

Use Of Effect Varnishes

The other important development is use of effect UV varnishes which create eyecatching different matt,gloss,texture,sand,embossed and many other effects usually by screen printing. It is a post printing finishing technique. As the name designates it is used to add some effects on the printing substrates to grab the audience attention. It is not only appealing but it also makes the printing process more complicated so the counterfeiters are not able to duplicate the product packaging. It is widely used in cosmetic and mobile industry.

These effects are mostly created by using screen printing technology. Meshes of different thickness are used to get variety of varnish layer on the stock. It can be done manually and fully automatic flatbed screen printing lines. There are many types of such varnishes like embossed, texture, sand, bubble, wrinkle, snowflake, and glow in dark, fragrance burst etc.

CustomBoxesClub USA is a industry leader who has introduced this finishing technique in the On line printing business.Please feel free to call our packaging specialist who always works as your team members at +1 (732) 481-2937

or email us at sales@custombkesclub.com